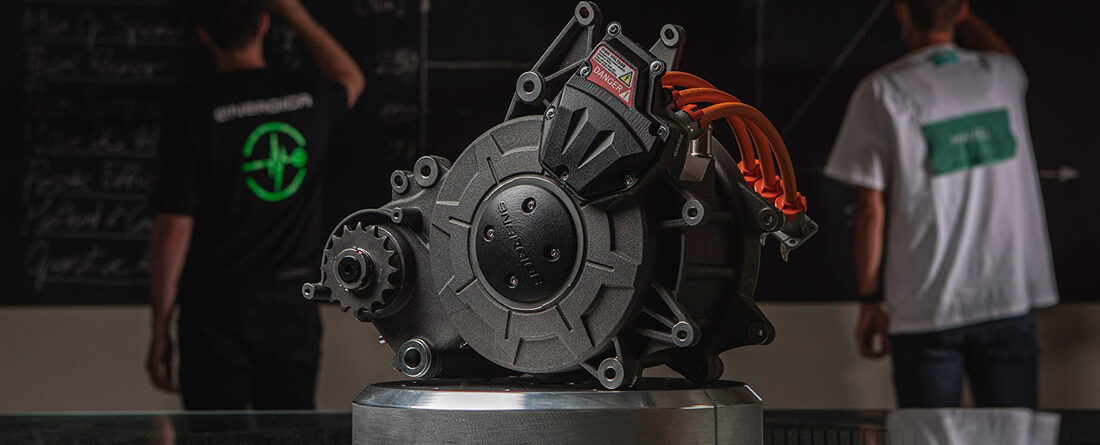

FROM THE MADE IN ITALY SKILLS OF ENERGICA MOTOR COMPANY S.P.A. AND MAVEL IS BORN EMCE, THE NEW ELECTRIC MOTOR OF ENERGICA MOTORCYCLES

Energica presents EMCE, the new electric motor created in co-engineering with the Italian company Mavel.

The name of the new EMCE motor is the acronym of Energica Mavel Co-Engineering and was born as a direct expression of the mentality of the Modenese motorcycle manufacturer, which every year focuses on technological innovation and the improvement of already high technological performance.

Mavel is a research, development and production company specializing in the electronics and automation sector based in Point-Saint-Martin, in the Valle D’Aosta, in a former hydro-electric power plant. As evidence of the great competence of Mavel, it is important to note that the company collaborates with the main international OEMs operating in the automotive sector, but with Energica makes its debut in the two-wheeled sector.

The new Powertrain will in fact be used exclusively on the entire Energica range.

“Innovation is the main strength of our technical department which, together with Mavel, has found the perfect collaboration to push the limits of current technology, further improving an already high-performing product.” Says Giampiero Testoni, CTO of Energica Motor Company S.p.A.

“The introduction on the market of the new EMCE engine was scheduled for release in 2022, but following the difficulties of our supply chain – due to the global pandemic situation – we decided to anticipate this timing and instead, in just 6 months we have developed this co-engineering with Mavel, into our current model year production.”

“Progress is what drives us to look beyond, all for the benefit of our end customers. We are proud to place a major new technological advance in the Electric Valley that, day after day, we are building with so much commitment and passion.”

The technological collaboration that characterized the co-engineering between Energica Motor Company S.p.A. and Mavel is directed to the search for solutions that optimize the efficiency of the system. Among the main advantages that contribute to improving the performance of the motor and inverter we find:

- Innovative rotor and stators’ geometries that minimize energy losses and maximize performance. The uniformity of the torque delivered and the optimization of the weights make the engine unique in terms of power and torque density and allow the optimization of production processes;

- Innovative and patented cooling of the rotor capable of generating an internal flow of air that laps the magnets and cools them. This allows the engine to exploit its potential even at high speeds;

- Adaptive control algorithms that ensure that the inverter is always able to operate the system as efficiently as possible;

- Patented sensors capable, among other things, of collecting and storing the operating data of the motor to predict the onset of any mechanical failure.

Thanks to the new EMCE motor, peak power increases to 126 kW at 8,500 rpm and with a liquid-cooling method that guarantees greater performance, Energica motorcycles will now be lighter by 10 kg, with a relative increase in range of 5-10% according to riding style.

Liquid cooling allows for better thermal conditioning of the motor and inverter, which translates into the ability to work with greater torque and power density which, even with a smaller in volume and lighter motor, leads to greater acceleration. Among perceptions in riding an Energica motorcycle with an EMCE engine, we find above all an improvement in handling. The transition from oil cooling to liquid cooling, present in the EMCE motor, is further demonstration of the technological advances which, year after year, contribute to the successes of Energica Motor Company S.p.A.

As Livia Cevolini, CEO of Energia Motor Company S.p.A. has pointed out, “We constantly receive messages of appreciation from our customers and this is why we continue to advance and develop in order to maintain our edge over all others. And it’s our determination to keep this edge into the future.”

The localization process implemented by Energica Motor Company S.p.A. now finds maximum expression with the EMCE project. In this way, the Modena-based company aims to enhance its “Made in Italy” engineering and have a positive effect on a supply chain situation.

Thanks to local production in Italy, it becomes possible for Energica to shorten the timeline for motors and avoid future delays in the supply chain, demonstrating how the company is able to respond promptly and proactively to difficulties arising from external factors. The EMCE engine will first be available in Europe and the USA, while the APAC market will have to wait until autumn.

Inside the EMCE motor, we therefore find all the passion of the Motor Valley and the renowned skills behind the words “Made in Italy”.